Nissan Serena 2004 with 2.0 liter engine. They tried to repair the car in another car service, but apparently to the touch. We could not connect with the scanner because the diagnostic connector is on 14pin. Such connectors are not in trend today …. The owner was looking for a long time, who can connect and identify the cause. The car slowly rolled over. As a result, the engine could be started, but the car categorically refused to go. Therefore, with the engine running, to facilitate driving on the move, and on a cable, the car arrived at our service station. We are connected by the scanner, then select individual parameters. I take into account the circumstance which system I have in front of me.

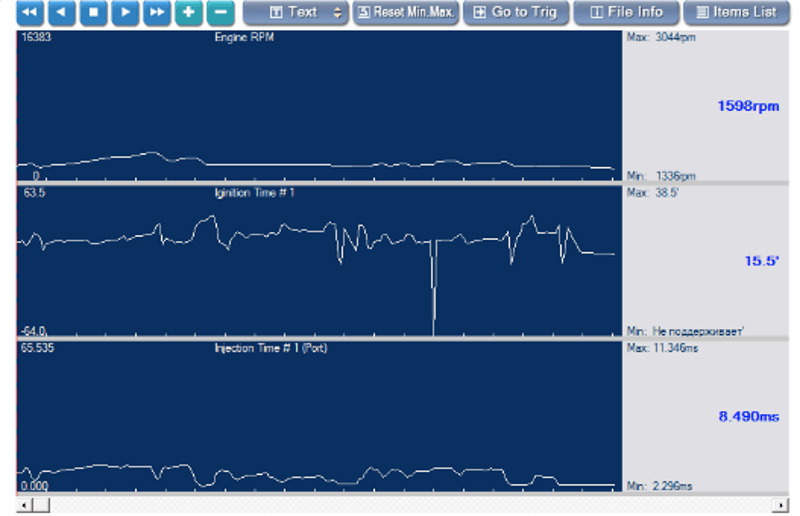

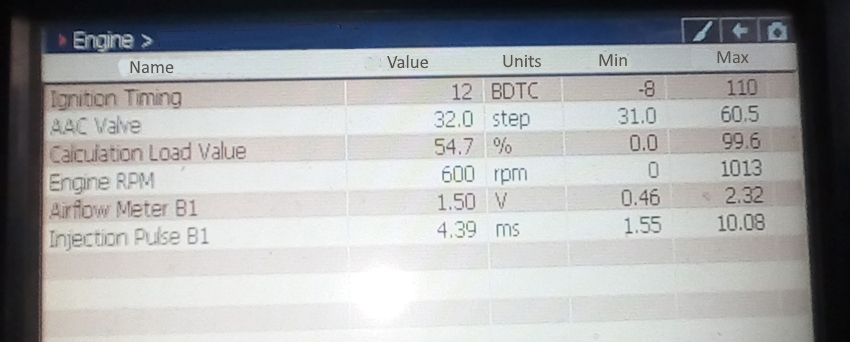

I consider all parameters in relation to the main parameter – engine speed. The ignition timing at idle is 12. When you press the pedal, the ignition angle jumped in the opposite direction to “-8“, and the engine speed reached its maximum value of 1013 rpm. If you look at how many steps the idle control valve opened at the same time, then we can assume that the pedal was pressed “well” enough and the speed should be at least 3000 rpm. And the minimum speed value is “0”, which means that the engine has stalled. The value of the ignition advance angle is 110, which corresponds to the ignition on the car with the engine not running. In short, after viewing the data, there is a firm conviction that the malfunction is not one, but at least two: in the ignition system and in the air.

Now, why also by air? See MAF readings at 0 rpm. Should be 1.03 (allowed) – no higher. And here below. At the same time, the sensor worked both at idle and when the pedal was pressed. But with the engine running, if you move the harness at the connector, the engine stalls. And the sensor output showed 0. And confidently and steadily, including when scrolling with the starter. The pin on the connector has been replaced. This fault was discovered during the test. The need to tighten the contact in the connector sometimes arises, but this should not be done so fanatically (no need to apply super efforts).

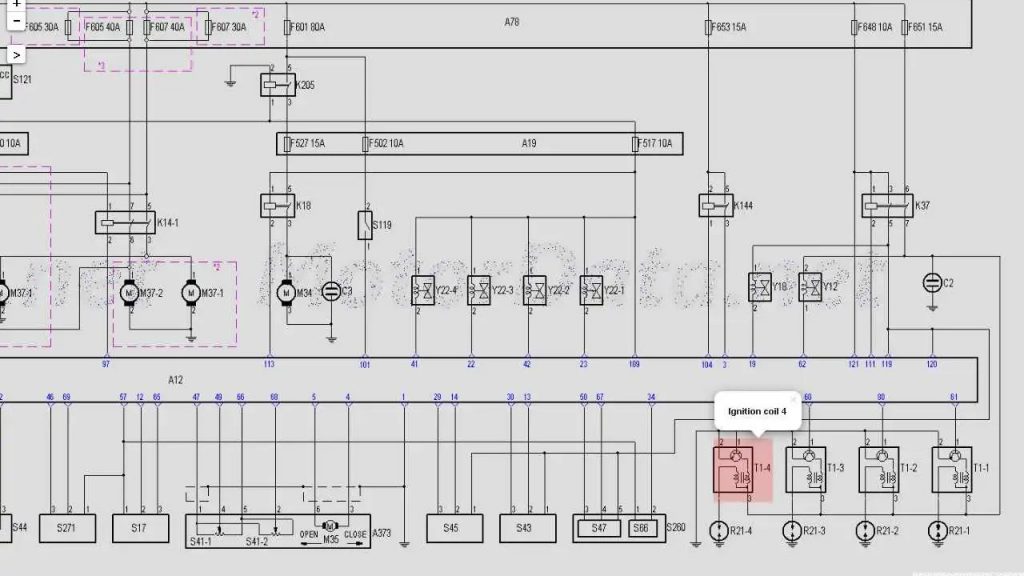

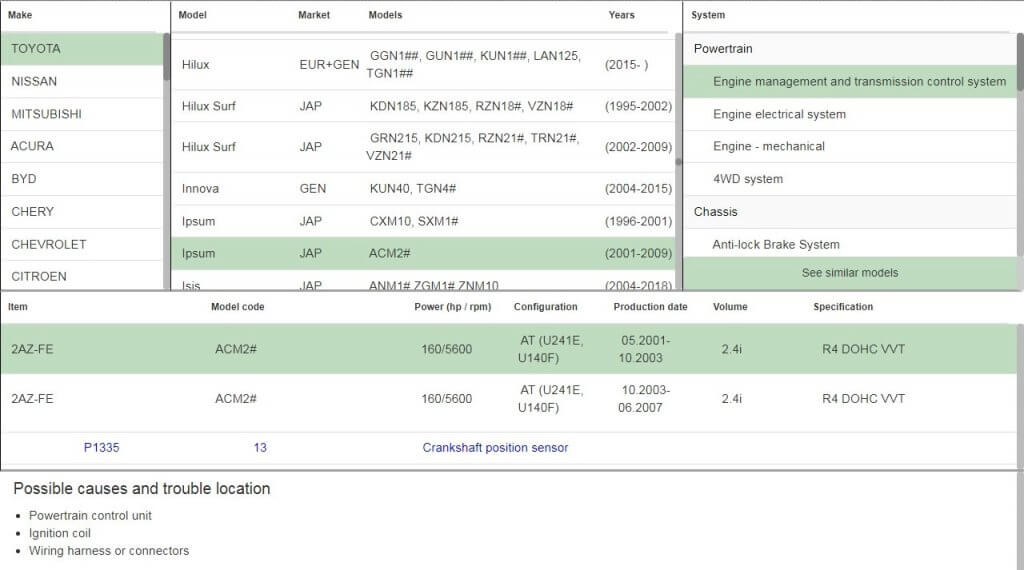

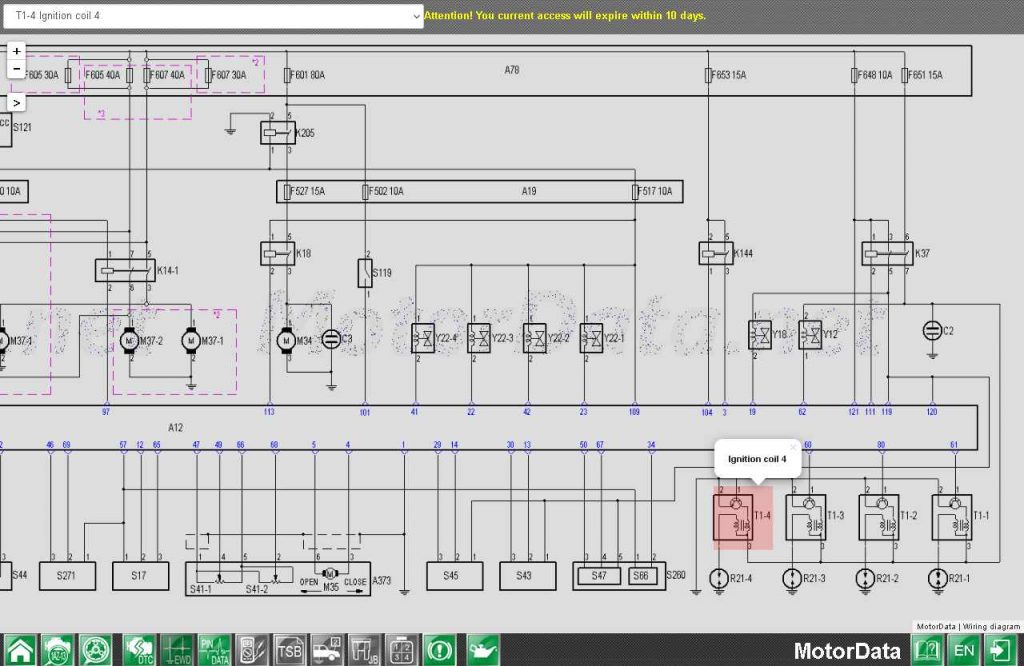

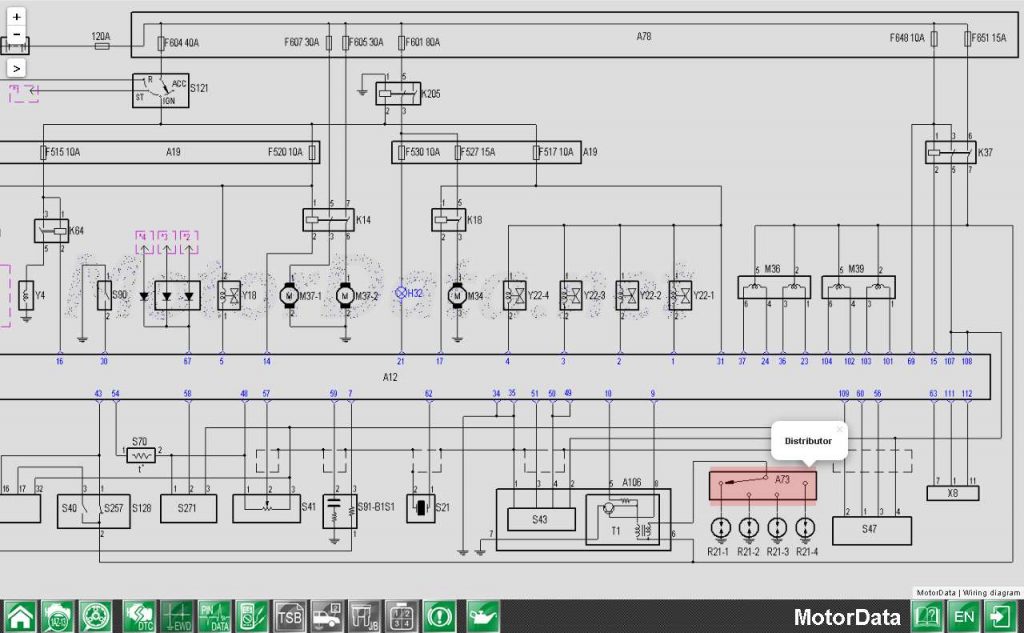

Now we need to remember the 2.0 liter engine. On these models, two engines of the SR and QR series were simultaneously installed. Many diagnosticians do not pay attention to the small differences between these engines, especially in the differences in the engine management system. And if there is a difference in the control object, then there will be a difference in the control body. Let’s see what the difference is, it can be clearly seen in MotorData:

On this SR20DE engine, instead of a camshaft sensor, a distributor is installed. So a small nuance, but changing the very approach to the analysis of ignition timing data. This device incorporates both a sensor and an ignition coil one for all cylinders, and the spark is distributed through a rotating contact – a rotor. In this case, we have a composite control element in the ignition system. And the point is not even that the distribution of the spark to the cylinders occurs mechanically. The bottom line is that high voltage is supplied to the candles through high-voltage wires from the coil and it passes through a large number of contacts. Where each contact is a place of possible malfunction.

We are looking:

Distributor. Everything listed above is inside it. The slider contact burned to plastic, even a spark melted the plastic. This is the contact through which the distribution to the cylinders takes place.

Ignition distributor cover. And here, too, contacts. Those that are on the cylinders also burned out. And if you add another burned-out rotor and a central contact, which generally burned out! There should be a coal in the center, it is spring-loaded and protrudes by 5-8 mm. When the ignition distributor cover is put on, it is pressed against the rotor, providing reliable contact. Therefore, we have an explanation for the current parameters. The spark simply cannot come on time, it is late (-8), since it takes time to break through these gaps that have arisen. The system, as far as it can, corrects the situation by adjusting the ignition angle. That’s all the explanation of the current parameters and the test. What kind of speed is there, it’s good that the engine generally started at the same time. But the candles and wires were replaced in the previous car service.