TOYOTA IST 20081NZ-FE. The fault is not that complicated or special, but the time was spent more than the description of this article. I would say that such faults are difficult to analyze, although they are inherently simple. Until you check all possible versions, you lose time. Therefore, I will not show any parameters, the tests are the same. I’ll show you the localization.

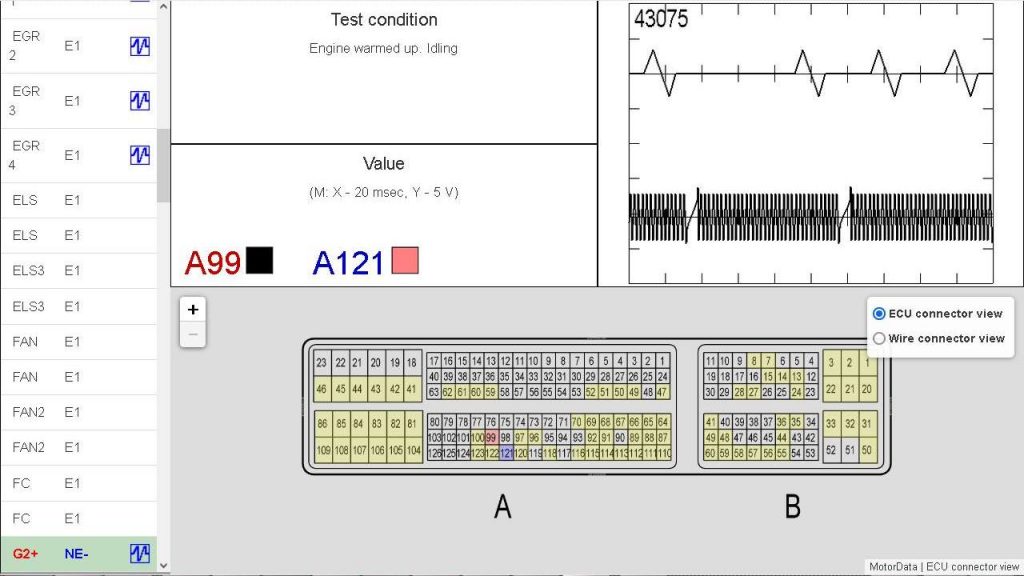

Started working with the scanner. Traditionally, in that part of the control, where the command has already been formed and transmitted to the actuators. Why? Yes, because in this part most often there are malfunctions. Because in this part, tests are carried out that allow you to make additional adjustments, check the actuators, track the change in parameters and find a malfunction. The methods for each may be different, but a certain sequence must be followed and there should not be any untested sections. Here I want to clarify: when troubleshooting – management, as a process, it is necessary to consider NOT AS A SINGLE WHOLE, but by the stages of which it is composed. The stages are implemented in a strict sequence with a given algorithm:

Control = receiving data + generating and transmitting commands to actuators + regulation (execution of a command) + feedback or control

So, after the inspections, it became obvious that the first stage in management was left to the last turn … but in vain. The puzzles were folded in such a way that “That’s the heart of the matter” is here. It’s okay, once again practiced in the analysis of parameters. We fix the situation.

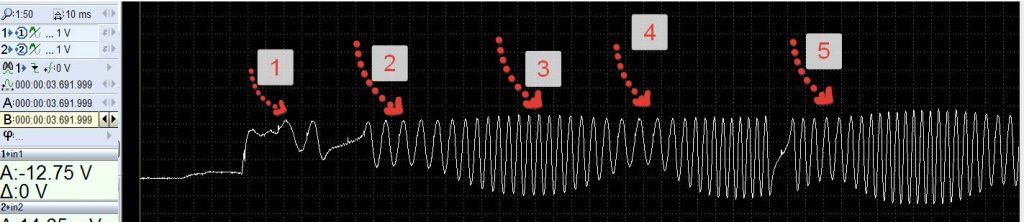

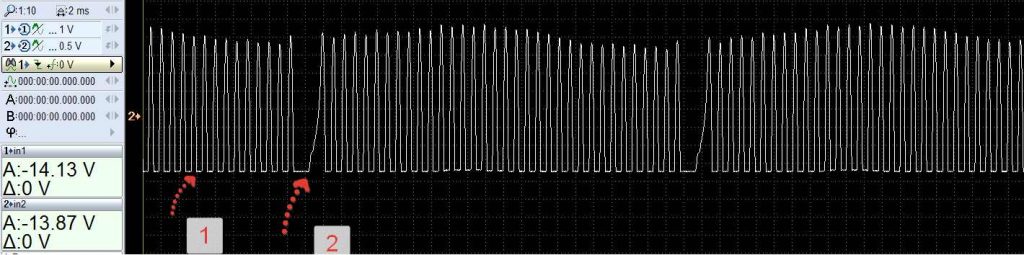

This is the signal from the crankshaft sensor. I don’t connect the camshaft sensor, there is hardly any desynchronization, I work with one probe. The numbers 1 and 2 marked the distortion of time intervals in the pulse sequence. And this distortion when converted to a number (definitely) = incorrect signal (information) of the ECU. The fact that the amplitude floats is understandable, the type of sensor is induction, the revolutions float. We look at the benchmark and compare.

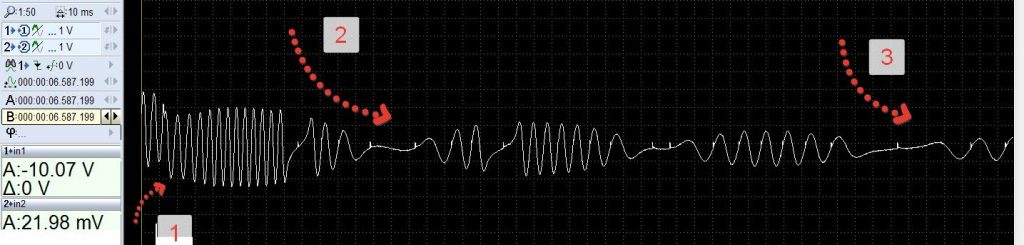

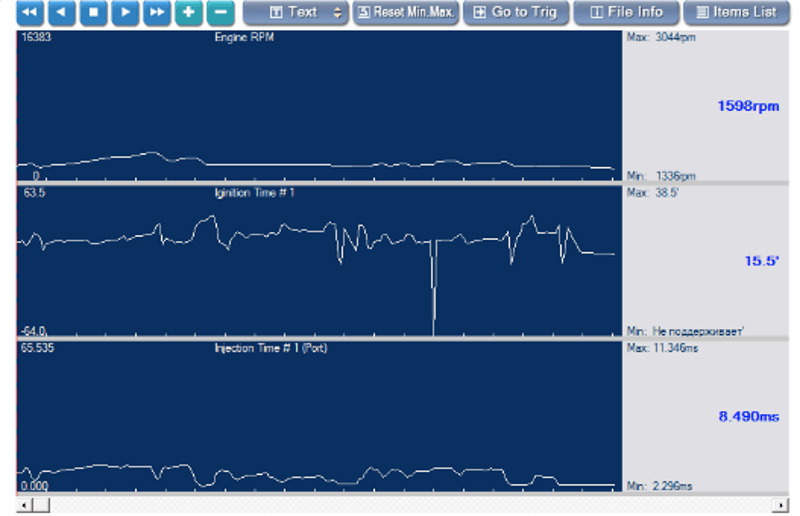

Conclusion: The sensor is faulty. I substitute a known-good sensor for a replacement from my warehouse. I start the car. She starts and works. After a while, I realize that something is not working right. Yes, and the launch was kind of “sluggish” … But these are sensations – they can fail. The scanner will now put everything in its place, but did not have time to connect, the engine stalled. BUT not immediately, but lowered the speed to the minimum allowable and twitched for about 10 seconds.

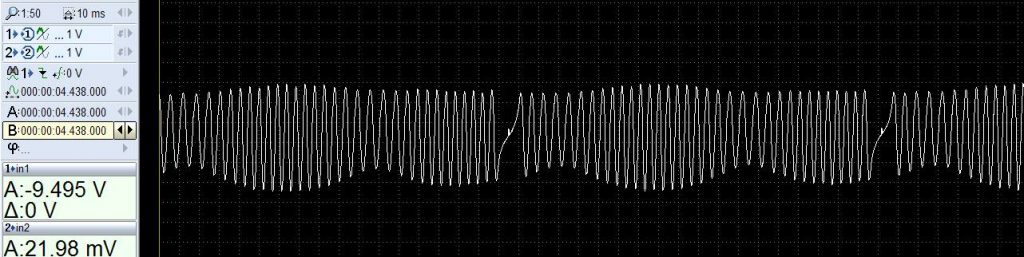

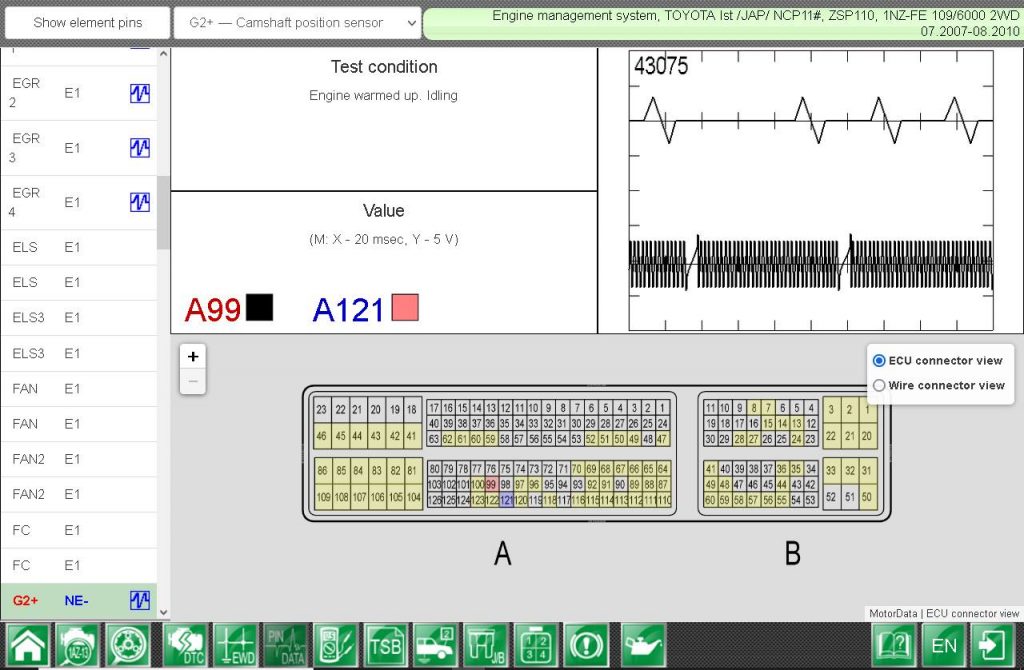

In such situations, take a step back, or even two, or even start all over again. Time was spent on the penalty loop, and returned to what the first time. Yes, this can not be! I connect the oscilloscope again, but now to the “known good sensor”. I’ll give the oscillogram in parts, I had to record it for some time until the car stalled.